You are now (finally!) ready to start coding.Īs I think is pretty obvious, being able to simply place a 0,0 point, and get the drawing to map the list of points would be a great help.Map the list back to the points - can be done by pencil on a print, however I drew leader lines to each point and labeled them with the point numbers.

Copy from the text editor into the text tool on the drawing.

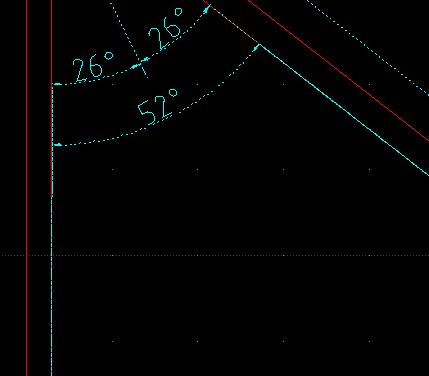

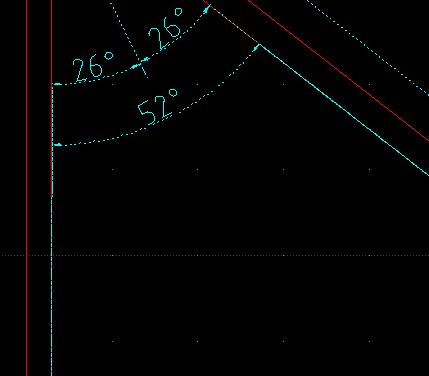

Copy from the text editor into the text tool on the drawing.  Cut and paste the list into your favorite text editor - remove everything except the X / Y coordinates (optional - number the points). Use the "Info" -> "List entities" menu to get a list of the selected entities - which SHOULD be just the points. Using the Draw Points function, place a point at each point of interest on the drawing - following the expected tool path will help later. Define the layer color and pen-size to be big enough to easily see. Create a new layer - be creative name it "points". (Use the desired 0,0 point for the reference, and paste it onto the origin in the new drawing) If the drawing's 0,0 point isn't where you will want it for coding, open a new drawing, and copy / paste the old one. Some machines have trouble with arcs more than a certain number of degrees, so the ability to add extra points on a feature is usefulĪs an example of how I solved the problem when I encountered it and was inspired to make the feature request which worked but was tedious even on my fairly simple part In this case the working point is the location of the mill cutter, but G-code is pretty much the standard for most CNC machines, so it could be a plasma-cutter, laser, water-jet, 3-D printer head, and so on.Įssentially what is needed for this function is to have the ability to set the location of the 0,0 point and define the points of interest, which are mostly going to be line intersections, center points of curves and other such locations. (Gross over-simplification, but good enough for this purpose) In both cases having X / Y coordinates is incredibly helpful as you essentially are telling the tool to move the working point to different X/Y positions, with intermediate stuff that tells it what to do on the way. I have two machines with different operating systems that I have to work with - one is an old Matsura VMC that uses G-code, the other is a Sharp mill with a proprietary "conversational" interface. Yes, Smallfix, it's pretty much as you describe it, with the added ability to specify the 0,0 coordinate that the other points are measured from. I wouldn't think this would be that terribly difficult, since the program already knows the cursor position.įirst off, thanks for tackling this one - I suspect it won't be terribly hard to do, but I'm not a programmer, so that is just a guess on my part. If the measurement function could have the ability to print the X-Y coordinates of a selected point, I feel like it would be a useful addition.

Cut and paste the list into your favorite text editor - remove everything except the X / Y coordinates (optional - number the points). Use the "Info" -> "List entities" menu to get a list of the selected entities - which SHOULD be just the points. Using the Draw Points function, place a point at each point of interest on the drawing - following the expected tool path will help later. Define the layer color and pen-size to be big enough to easily see. Create a new layer - be creative name it "points". (Use the desired 0,0 point for the reference, and paste it onto the origin in the new drawing) If the drawing's 0,0 point isn't where you will want it for coding, open a new drawing, and copy / paste the old one. Some machines have trouble with arcs more than a certain number of degrees, so the ability to add extra points on a feature is usefulĪs an example of how I solved the problem when I encountered it and was inspired to make the feature request which worked but was tedious even on my fairly simple part In this case the working point is the location of the mill cutter, but G-code is pretty much the standard for most CNC machines, so it could be a plasma-cutter, laser, water-jet, 3-D printer head, and so on.Įssentially what is needed for this function is to have the ability to set the location of the 0,0 point and define the points of interest, which are mostly going to be line intersections, center points of curves and other such locations. (Gross over-simplification, but good enough for this purpose) In both cases having X / Y coordinates is incredibly helpful as you essentially are telling the tool to move the working point to different X/Y positions, with intermediate stuff that tells it what to do on the way. I have two machines with different operating systems that I have to work with - one is an old Matsura VMC that uses G-code, the other is a Sharp mill with a proprietary "conversational" interface. Yes, Smallfix, it's pretty much as you describe it, with the added ability to specify the 0,0 coordinate that the other points are measured from. I wouldn't think this would be that terribly difficult, since the program already knows the cursor position.įirst off, thanks for tackling this one - I suspect it won't be terribly hard to do, but I'm not a programmer, so that is just a guess on my part. If the measurement function could have the ability to print the X-Y coordinates of a selected point, I feel like it would be a useful addition.

Needless to say, this is a nuisance, and sort of begs the question of why we can't use a computer to do this grunt work. After that, as a visual aid, I have to HAND COPY the coordinates onto a printout of the drawing. I then select the points and do a "List Info" which gives their coordinates. I then move the drawing to put one of the points on the 0,0 grid position (this isn't essential, but it makes the rest easier) and turn off the display of everything except the points layer. The only way I've found to get the info I need is to create another layer in the drawing where I create point entities at the end of each line entity, or other feature of interest. I can't find any way at present (Version: master SCM Revision: 2.0.0beta1Ĭompiled on: Jan 10 2013) to make LibreCad produce X-Y labels on the drawing the way that it does linear measurements.

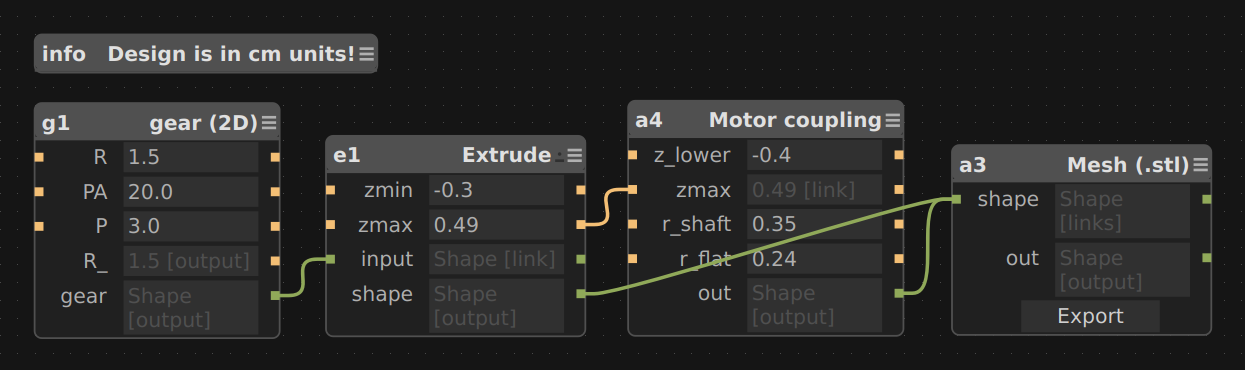

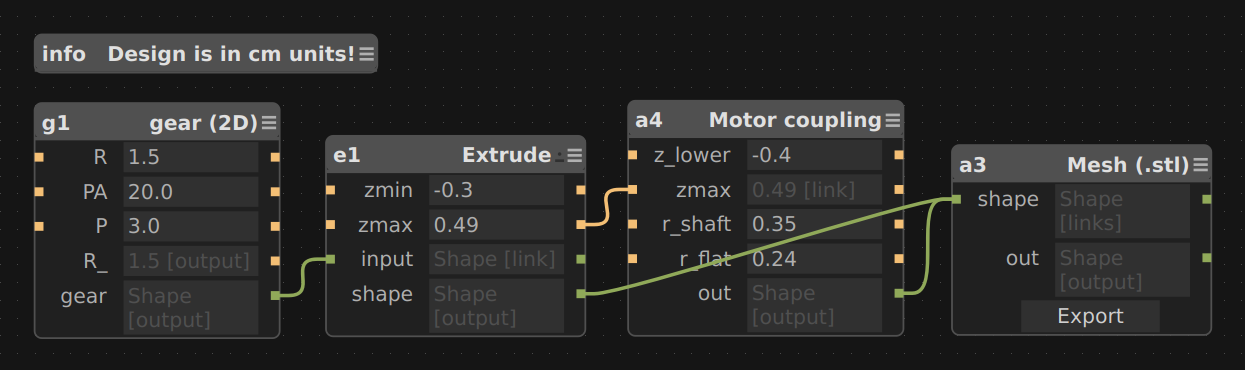

Making it more of a pain, is that the mill ONLY accepts X-Y coordinates of distance from a datum point. Unfortunately the only way that I have to program the mill is to manually enter the program information - I'm not sure if we have the ability to do remote programing, and even if so, the machine expects "G-code" which AFAIK LibreCad can't produce. One of the things that I use LibreCad for is to make drawings of parts that I will subsequently make on our Sharp 2-axis CNC mill.

0 kommentar(er)

0 kommentar(er)